Screw Barrel Guide: Selection and Maintenance

A practical guide on screw barrel concepts, selection and maintenance for reliable extrusion with new or second hand equipment.

Plastik sektöründen güncel bilgiler ve teknik rehberler

A practical guide on screw barrel concepts, selection and maintenance for reliable extrusion with new or second hand equipment.

A concise glossary for newcomers. We explain core terms—screw-barrel, L/D ratio, zones, vacuum, gearbox, die—without sharing settings, recipes, or process know-how.

Discover how to evaluate a used extruder, focusing on mil-kovan, twin-screw systems, and compatibility with your granule processing.

Extend screw-barrel life with best practices on materials, thermal profile, pressure control, alignment and data logging.

A concise checklist for choosing an 80/156: screw/barrel metallurgy, drive train, thermal control, automation and service—tailored for PVC/WPC producers.

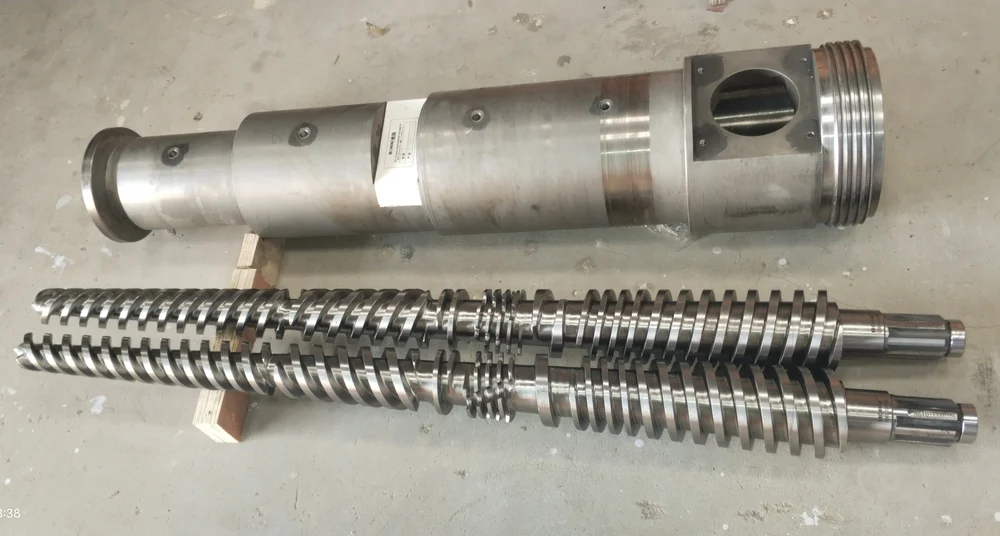

Three main barrel types—conical twin-screw, parallel twin-screw, and single-screw—optimize extrusion for any polymer with superior mixing and efficiency.

An extruder machine is an industrial machine that performs heating, mixing, and shaping processes of plastic raw materials.

A PVC raw material mixer is an industrial machine that ensures homogeneous mixing of polyvinyl chloride resin with additives.

A granulation machine forms the core of plastic processing, combining melting, mixing, and granule sizing in screw-and-barrel systems, often with twin-screw advantages.

Plastik işleme makineleri hakkında uzman görüşü almak için bizimle iletişime geçin.

Request Quote