When is 80/156 the right choice?

High-torque PVC/WPC profiles, panels and pipes

Broad tooling compatibility and multi-die lines

Handles recycled blends and high-filler recipes

Key criteria

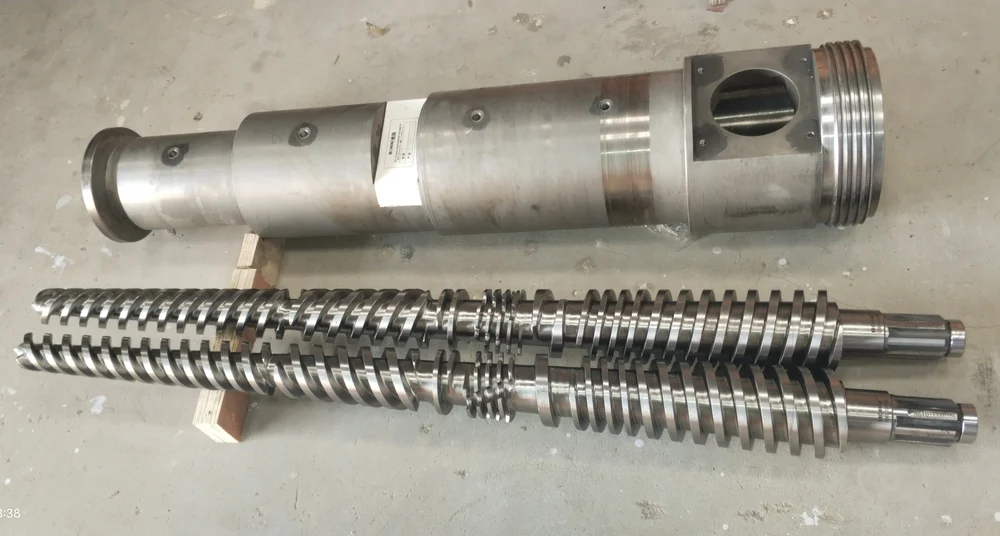

Metallurgy: nitrided or bimetallic barrel; wear class and hardness.

Drive/gearbox: low vibration, easy maintenance.

Thermal control: zoned PID, proper TC placement, air/water cooling.

Automation: recipe management, trend logging, secure remote access.

Energy: VFDs, insulation, optimized zone layout.

After-sales: commissioning, operator training, spare parts.

Common pitfalls & maintenance tips

Don’t size on nominal throughput alone; tooling and recipe dominate.

Standardize start/stop; avoid cold starts.

Screen material and track vibration trends.

Meta Title (EN)

80/156 Conical Twin-Screw Extruder Guide | Dereli Plast (2025)