Why a Glossary?

Extrusion involves many parts and concepts. This article explains only the basics in plain language—no machine settings, recipes, or proprietary methods.

Key Terms

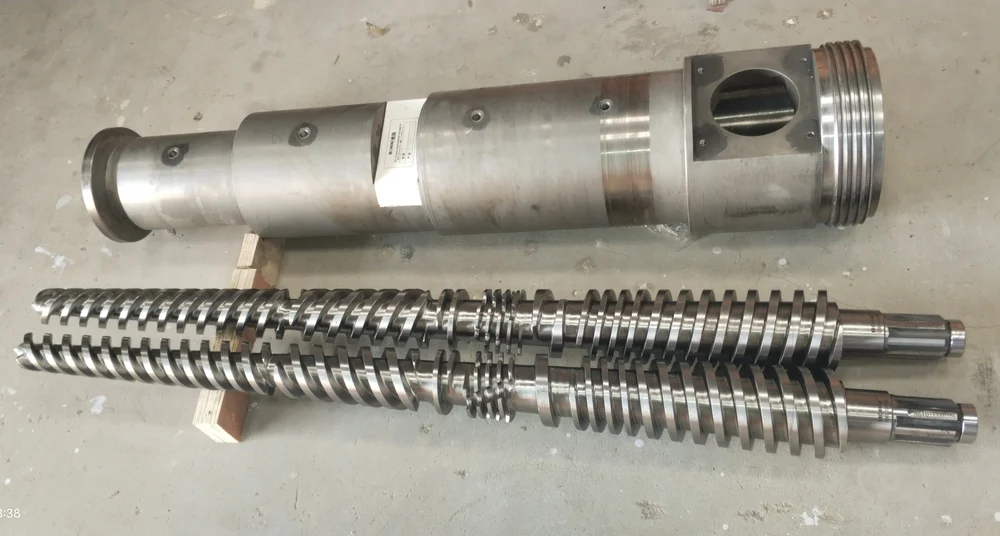

Screw: Conveys and helps melt material.

Barrel: Cylindrical housing with heating zones.

Screw-Barrel Set: Central to output and quality.

L/D Ratio: Length-to-diameter; design indicator, not a universal “best.”

Zones: Discrete heating areas along the barrel.

Gearbox & Drive: Provide torque and speed control.

Vacuum: Helps remove gases in relevant applications.

Die: Shapes the molten material; works with calibration/cooling.

Buying Checklist

Service & spares, warranty/docs, references, energy & maintenance access.

FAQ

Best L/D? Depends on product/formulation.

How many zones? Depends on configuration & target product.

Which resin is best? Application-dependent.

How to notice wear? Performance drifts & visual checks; detailed diagnosis needs expertise.

Standard settings? None—each line and recipe differ.

Internal links:

80/156 Conical Twin-Screw Extruder Buyer’s Guide (2025)

10 Effective Ways to Reduce Screw-Barrel Wear

Screw-Barrel Sets: Conical Twin, Parallel Twin, Single Screw