Introduction

Used extruders offer cost efficiency in plastic processing facilities. With proper evaluation and a clear maintenance history, they can deliver reliable performance. This article covers buying considerations, key concepts, and practical tips for second-hand extruders. It emphasizes mil-kovan (screw and barrel) systems, twin-screw configurations, and granule processing contexts.

Key Concepts

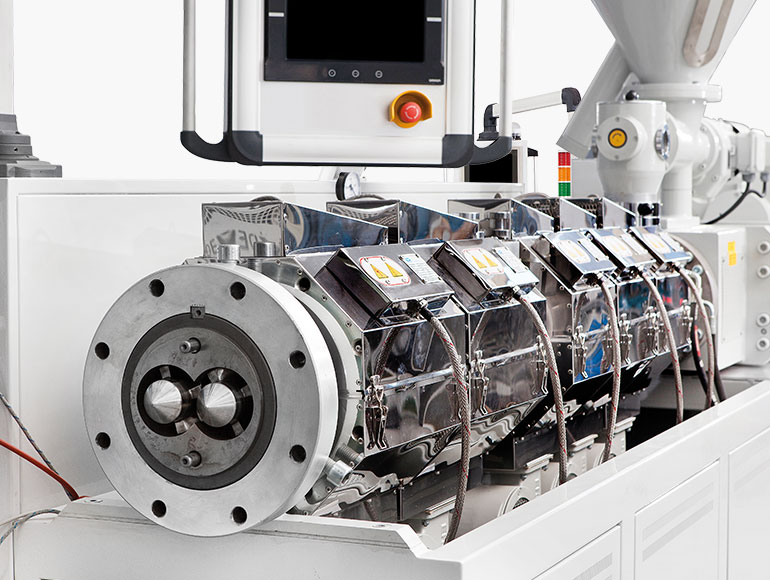

An extruder is a machine that heats and plasticizes pellets and forces the material through a die or profile. Key terms include:

- Screw (mil): the rotating shaft that pushes material forward.

- Barrel (kovan): the housing that surrounds the screw and provides heating zones.

- Twin-screw extruder: two intermeshing screws, offering improved mixing and flow control.

- Granule machine: a broad term for equipment handling plastic pellets during processing.

- Used extruder: a second-hand unit where service history and current condition influence reliability and ROI.

Applications / Tips

When evaluating a used extruder, consider:

- Exterior condition: corrosion, cracks, seals, electrical panels.

- Screw and barrel wear: assess wear patterns, end seals, and possible damage.

- Heating/cooling controls: verify zones operate correctly and temperature control is accurate.

- Drive motor and gearbox: motor power, gearbox wear, alignment, and lubrication.

- Control system and electronics: compatibility of PLC/HMI with your line.

- Service history and spare parts: availability of parts and documented maintenance.

- Electrical safety and wiring: intact insulation and proper grounding checks.

- Test run: perform a controlled run to observe output quality and stability.

- Installation considerations: alignment, mounting, and integration with downstream equipment.

Common Mistakes

- Choosing the lowest price without verifying wear on critical components.

- Selecting screw/barrel combinations incompatible with your process or resin type.

- Ignoring service history or assuming parts are readily available.

- Overlooking energy efficiency and drive compatibility.

- Assuming exterior good condition guarantees interior integrity.

Conclusion

Used extruders can be a prudent investment when evaluated thoroughly, with documentation of maintenance and clear part availability. For tailored assessments and safe, informed decisions, contact our technical team for a status review and recommendations.