Introduction

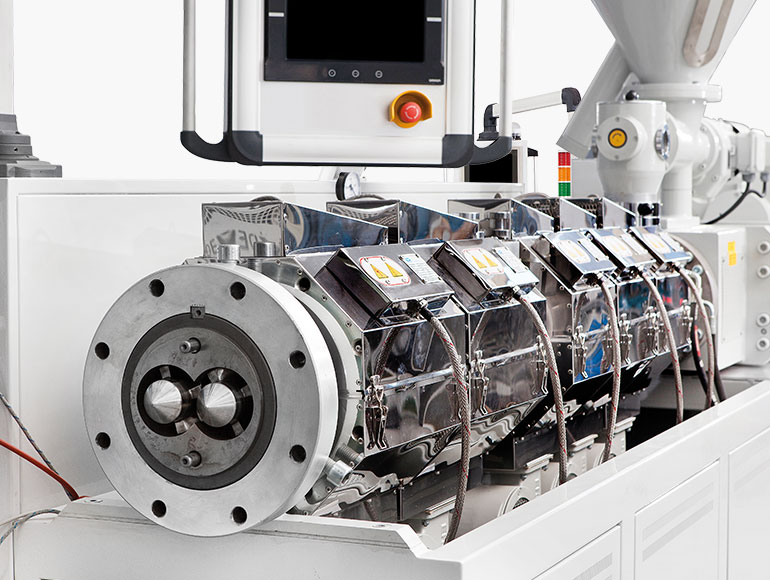

Twin-screw extruders are a core piece of equipment in plastics processing. The interaction of two intermeshing screws inside a barrel governs melting, mixing, and conveyance of the material from feed to a homogeneous melt. The barrel-screw system plays a pivotal role in heating, melting, and homogenizing polymers. In many cases, refurbished (second-hand) extruders offer a cost-effective option for projects with budget constraints. This article outlines fundamental concepts, practical application tips, and common pitfalls to avoid.

Fundamental Concepts

A twin-screw extruder consists of two screws and a barrel. The screws rotate in a closely intermeshing manner to convey and melt the polymer, enhancing mixing and homogenization. Key concepts include:

- Throughput and L/D ratio: Governs residence time and melt quality.

- Screw geometry (compression, barrier, mixing elements): Material-dependent design choices.

- Barrel and venting: Removes volatiles and prevents melt defects.

- Backpressure and die head: Influences melt temperature and fill quality.

Applications and Tips

Fine-tuning parameters is essential for reliable operation. Practical tips include:

- Temperature profile: Zoned heating to optimize melt flow and energy efficiency, with careful transitions between regions.

- Speed and feed rate: Set RPM and feed rate to maintain stable melt and consistent throughput.

- Material compatibility and drying: Dry hygroscopic materials properly to avoid hydrolysis and degraded properties.

- Screw design selection: Choose geometry based on material and desired output (e.g., polymer grade, additives).

- Vent design and backpressure: Ensure venting paths are clear to prevent burn and voids.

Common Pitfalls

Avoid these frequent issues:

- Inadequate venting leading to gas buildup and defects.

- Incorrect die or filter pack selection causing poor flow or contamination.

- Overheating or under-drying materials resulting in degraded properties.

- Improper cleaning causing cross-contamination.

Conclusion

Twin-screw extruders offer process flexibility and high melt quality when operated with proper design and maintenance. Understanding core concepts, aligning parameters to material properties, and maintaining the equipment are key to achieving optimal performance. Refurbished units can be cost-effective when evaluated carefully.