Introduction

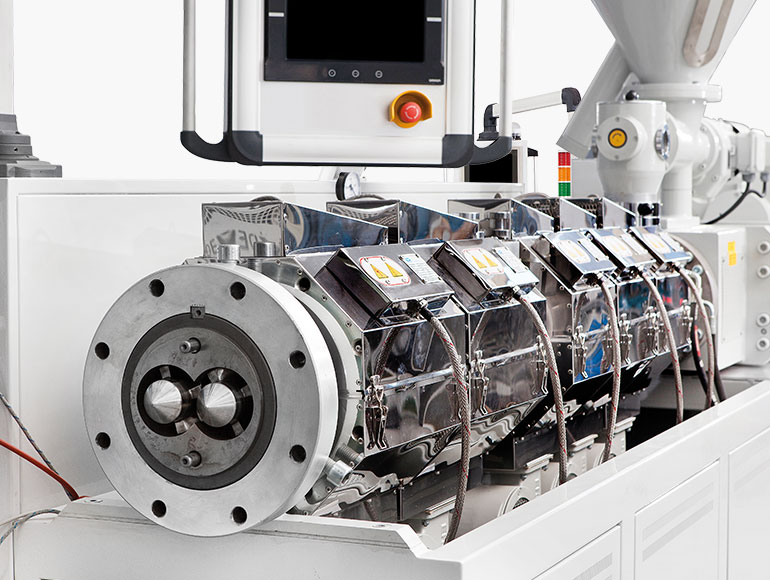

The screw barrel is a core pair in plastic extrusion, governing how erated material flows and is processed. The screw pushes and mixes the polymer while the barrel constrains and transfers heat, shaping the final product. Selecting the right screw and barrel affects production comfort, repeatability, and maintenance costs. This article targets professionals working with extrusion and granulation equipment, including considerations for second hand extruders. The goal is to balance efficiency and reliability through understanding of screw barrel concepts, practical tips, common pitfalls, and a concise conclusion.

Fundamental Concepts

Key relationships and terms form the basis for informed decisions:

- Screw: outer diameter, thread geometry and material hardness influence melting performance and mixing efficiency.

- Barrel: interior surface quality, material choice and heat transfer channels determine wear resistance and heat distribution.

- Coatings and materials: options include alloy steels, stainless steel and ceramic coatings for durability.

- L/D ratio: length-to-diameter ratio affects flow, pressure profile and residence time.

- Twin screw extruders: offer enhanced mixing and throughput but require careful matching of components.

- Second hand extrusion equipment: cost benefits must be weighed against wear and compatibility concerns.

Applications / Practical Tips

Practical guidance to optimize screw barrel performance:

- Define processing requirements: resin type, color, filler level and throughput guide selection.

- Material and coating choices: consider wear resistance and heat transfer properties for the chosen polymer.

- Alignment and assembly: ensure axial and radial accuracy, seal integrity and minimal runout to avoid leaks and wear.

- Thermal management: manage heat zones for stable melt quality; avoid overloading the system thermally.

- Maintenance: routine cleaning, proper lubrication and periodic inspection of seals improve reliability.

- Second hand considerations: check wear indicators, bore surface condition and tolerances; perform compatibility tests.

- Granulation integration: ensure screw and barrel design matches granulation throughput and feed system.

Common Pitfalls

A few recurring issues can degrade performance:

- Incompatible materials or coatings leading to rapid wear

- Inadequate cleaning causing residue build-up

- Ignoring thermal expansion resulting in misalignment

- Neglecting seals and gaskets

- Overlooking wear in used equipment

Conclusion

Choosing and maintaining the screw barrel assembly directly impacts extrusion performance. Correct material selection, coating, and an appropriate L/D ratio, along with careful assembly, increase reliability and product consistency. When using second hand equipment, monitor wear indicators and conduct thorough compatibility tests. This guide supports industrial professionals in reducing risk and increasing efficiency in screw barrel systems.