Introduction

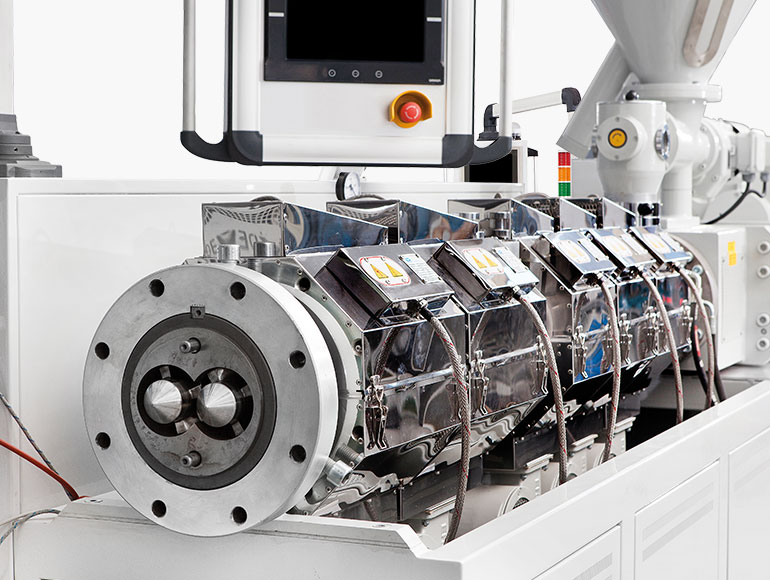

The extruder is the heart of a plastic processing line. It melts, mixes, and conveys plastic pellets to the die under controlled pressure and speed. This article focuses on screw-barrel systems, covering single-screw and twin-screw extruders, key components, and essential operating practices. We also discuss integration with a granulation machine and considerations when selecting a second-hand extruder.

Basic Concepts

The combination of a screw and a barrel governs material feeding, melting, and plasticization. Single-screw extruders offer simplicity and lower capital cost, while twin-screw extruders provide better mixing, higher fill, and more controlled melting. The L/D ratio influences melting efficiency and profile. Granulation machine integration plays a role in drying, material handling, and process stability. For used extruders, wear on the screw, barrel seals, and control system reliability are critical evaluation points. Understanding these concepts helps in making informed equipment decisions.

Applications and Tips

Choose based on material type, moisture content, and required throughput. Ensure pellet quality and drying where needed. Temperature profiles are set across zones, from the feeding line to the die, and screw speed and backpressure must be tuned for consistent melt flow and homogeneous mixing. When evaluating used equipment, inspect wear on the screws, barrel integrity, gearbox condition, and control panels. For granulation integration, select die configurations that match material behavior and downstream processing requirements.

- Feedrate and material quality: Adequate fill improves stability and reduces fluctuation.

- Temperature management: Avoid overheating to prevent polymer degradation and viscosity loss.

- Maintenance: Regular inspection of seals, screws, and sensors preserves performance.

- Used equipment checks: Verify motor alignment, gearbox wear, and control accuracy.

Common Mistakes

Common mistakes include under or over feeding, improper temperature profiles, and unbalanced backpressure. Incorrect feeding can cause burst or starvation, leading to product defects. Barrel or screw wear and poor seals can cause leaks and process instability. Inadequate maintenance shortens component life and raises safety risks. A disciplined maintenance and calibration regime is essential for reliable operation.

Conclusion

Choosing the right extruder and maintaining it properly yields improved efficiency, product quality, and operational reliability. For used equipment, thorough inspection and a renewal plan can lower total ownership cost. With a proper design and process discipline, material quality and production stability are achievable over the long term.